PC, Precast concrete, generally refers to the concrete structure which is assembled, connected and casted partly by using concrete prefabricated components as main component. Recently, it has widely been applied in residential and industrial construction project as one kind of structural style.

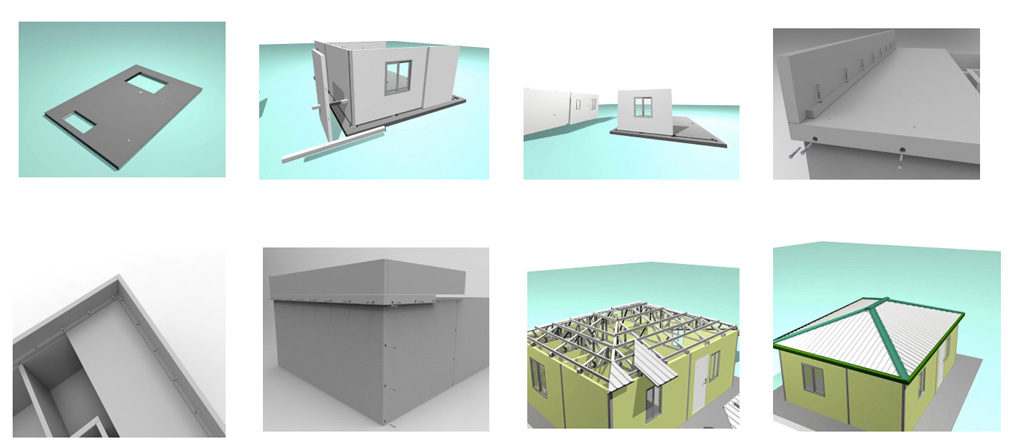

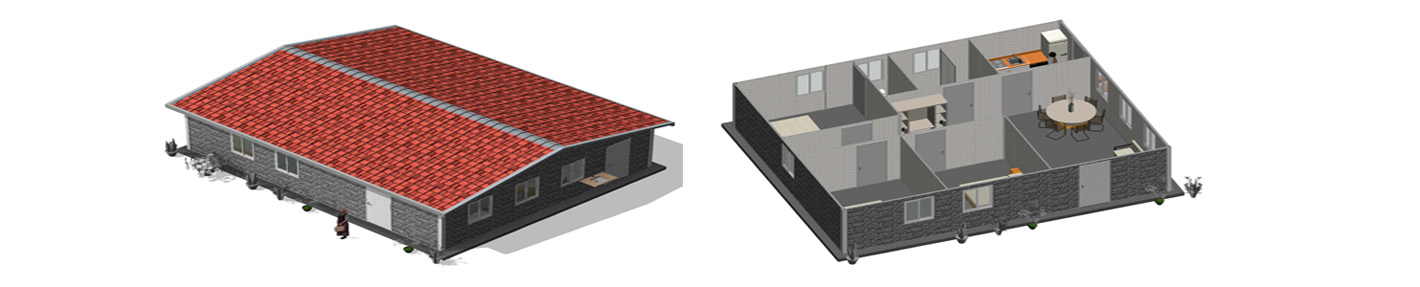

CCS PC structure takes ceramist concrete as raw materials with the advantages of light weight and high prefabricated. The whole frame structure is all made by modular units including walls and roofs.

The Advantages of PC Module Home:

- Shorter construction period: Major components can be prefabricated in factory, and delivered to the construction site with assemble. So it can save up to 1/3 construction period. And also it can reduce influence for surroundings because of the shortened time for mold and ripping of cast structure and maintain time for concrete.

- Energy conservation and environment protection: By perfect technology economic effect with fewer wet work in scene which can reduce waste of materials and energy; in favor of environment protection and keep people away from noise and dust.

- Modular manufacture and component with high precision: The size of construction conform to the module which means we can produce component with uniformly quality and high precision with smooth surface, good appearance, size accurate and request function of insulation, heat-resistance, Water and electricity pipe layout.

- Less wet work, help clean the construction site of civilization and the surrounding environment. Compared with the traditional buildings, steel structure weight can reduce more than 30%, greatly reducing the cost base.

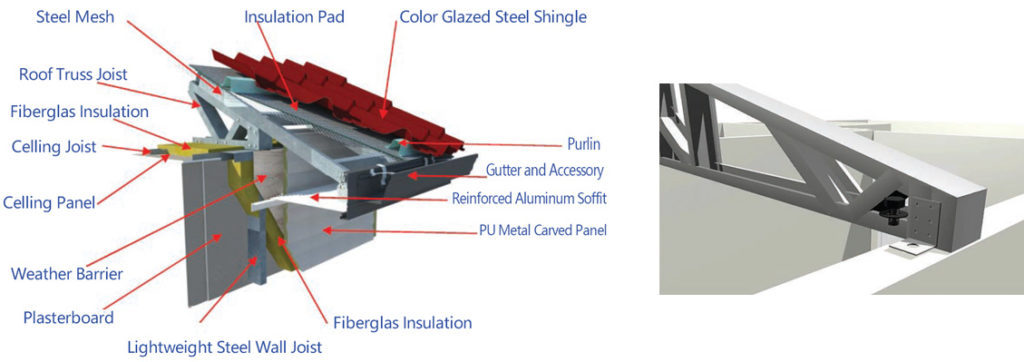

Roof System:

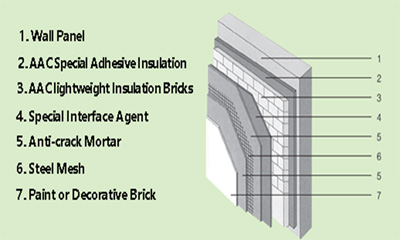

Wall System:

- ALC Wall Panel

- ALC Interior Wall Panel

Wall Panel Package:

- 75 mm Wall Panel.

- 100 mm Wall Panel.

Aluminum Post and Wall Panel Connection:

Installation: